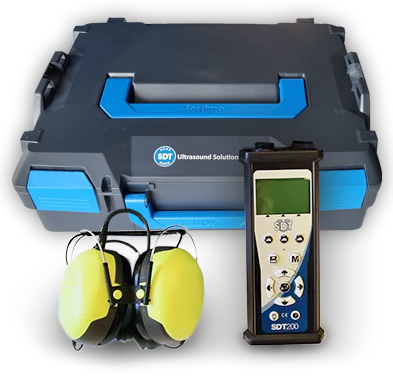

Description

Improve asset reliability with your SDT200:

| Mechanical Condition Monitoring Identify early-stage bearing defects to prevent unplanned failures. |

|

| Bearing Lubrication Monitoring The right amount of lubricant at the right interval |

|

| Compressed Air & Gas Leak Detection Find Air Leaks. Decrease Energy Consumption. Maximize Uptime. |

|

| Electrical Equipment Fault Detection Safely Inspect Electrical Systems with Ultrasound. |

| Steam Trap Testing and Maintenance Keep Your Steam Clean, Safe And Energy-Efficient. |

|

| Hydraulic Systems Monitoring Detect leakage, by-passing and blockages. |

|

| Valve Condition Monitoring When your valves are closed, are they really closed? |

|

| Tightness Testing Ultrasonic tightness testing offers a complete, global solution with unheard-of accuracy and reliability. |